Mobility: Remote Maintenance, Wherever You May Be

Managing industrial maintenance is an ongoing challenge and a never-ending process. Maintenance leaders and operational decision-makers face an ever-growing set of critical responsibilities, and keeping assets in optimal condition is essential to ensure production continuity and factory safety.

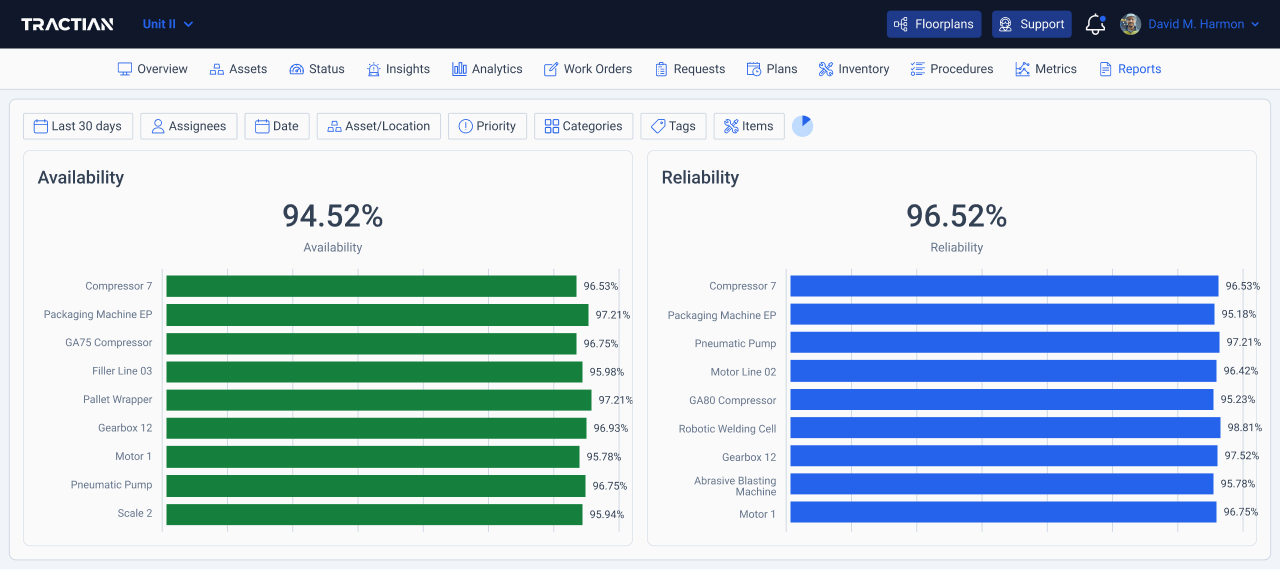

They must be experts in minimizing downtime and increasing asset availability, as any unplanned stoppage can lead to costly delays and revenue loss.

Managers also have the crucial task of ensuring workplace efficiency and safety by optimizing maintenance processes and ensuring resources are used effectively. The ability to analyze data and develop data-driven strategies is vital in modern maintenance management, as data sampling and analysis can reveal trends and patterns that help prevent issues before they happen.

Furthermore, it’s paramount that maintenance managers have a comprehensive understanding of all key maintenance indicators (KPIs). This involves measuring and improving KPIs like equipment efficiency, maintenance costs, asset reliability, and component lifecycle. With all these and other responsibilities to fulfill on a daily basis, having the latest, cutting-edge technology is essential to ensure everything runs smoothly.

Maintenance Mobility: Boost Your Results and Availability

Before, in order to manage all responsibilities, companies and maintenance managers needed to use various platforms, be constantly on-site reviewing operations, and stay connected to the internet at all times to have maintenance information at their fingertips.

Now, all activities can be simplified and optimized thanks to the TRACTIAN App, the market’s leading and most advanced asset and maintenance management application, powered by artificial intelligence.

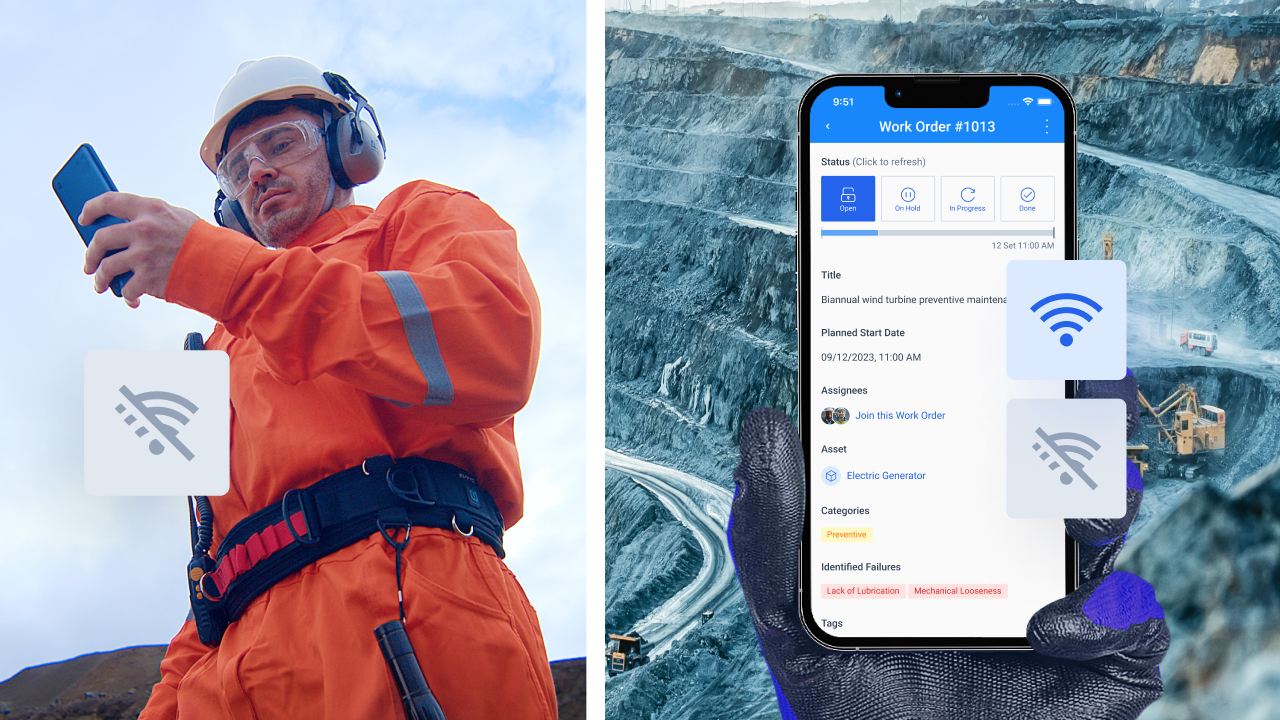

Mobility in maintenance management has become a necessity, as it allows everyone involved in the operation – from technicians to managers – to access critical information, record activities, and get real-time updates, and do it all from mobile devices such as smartphones and tablets, with or without internet.

This eliminates the need for a fixed location and improves efficiency and reliability at all stages of maintenance management. This is a giant step towards Total Productive Maintenance (TPM), where everyone in the operation is involved from wherever they may be in the plant.

And that’s why the TRACTIAN App stands out: its seamless integration with the entire maintenance operation. With advanced management and monitoring features, it provides teams with the ability to plan, execute, and monitor maintenance operations and assets efficiently. Its intuitive user interface ensures a quick learning curve, while maintenance planning, inventory management, and asset monitoring features make administration a breeze.

Furthermore, its integration with leading ERP systems, including SAP and Oracle, makes it indispensable for any industry. And now, all of this can be done without an internet connection. Read on to find out how to access this new feature and why it will become your best ally.

Start Exploring the TRACTIAN App

TRACTIAN App = 24/7 Visibility, Control, and Management

Our AI-assisted maintenance and asset management app is designed to give businesses complete control over their industrial operations. One of its key features is real-time asset monitoring using sensors and IoT technology that track variables like temperature, vibration, energy consumption, and power quality 24/7.

This enables companies to constantly monitor the condition of their machinery and equipment, gathering precise data that is crucial for making informed decisions.

In conjunction with the online monitoring platform and AI-driven fault diagnosis, the TRACTIAN App identifies potential failures before they happen, sending prescriptive alerts through the app, significantly reducing unplanned downtime and the associated costs of emergency corrective actions.

The TRACTIAN App also streamlines work order management, allowing for efficient PM creation, scheduling, and tracking. Users can plan these maintenance activities according to real-time data and always-updated KPIs provided by the app. Additionally, inventory management becomes more efficient with the platform, as it helps accurately track spare parts in stock and components needed for maintenance.

With a built-in chat, the TRACTIAN App encourages real-time communication among team members, making collaboration and problem resolution easier, while seamlessly integrating with ERPs like SAP and Oracle, ensuring data consistency and process optimization, without the need for procedural steps in external software.

TRACTIAN Receives SAP Certification and Arrives at SAP Store

Finally, it enables users to access and manage assets from anywhere, providing all maintenance and asset information, open orders, requests, and manufacturer manuals, delivering flexibility and accessibility to all maintenance operations.

Take all the information provided by the TRACTIAN App with you anywhere, anytime, with or without internet, and have visibility and control of your entire operation in a simplified and integrated way. The app’s offline mode takes maintenance management for everyone in the operation – from technicians and analysts to managers – to a new level of efficiency.

How Remote Maintenance Mobility Maximizes Efficiency

With the TRACTIAN APP, you’ll have access to crucial tools to optimize your maintenance management, such as:

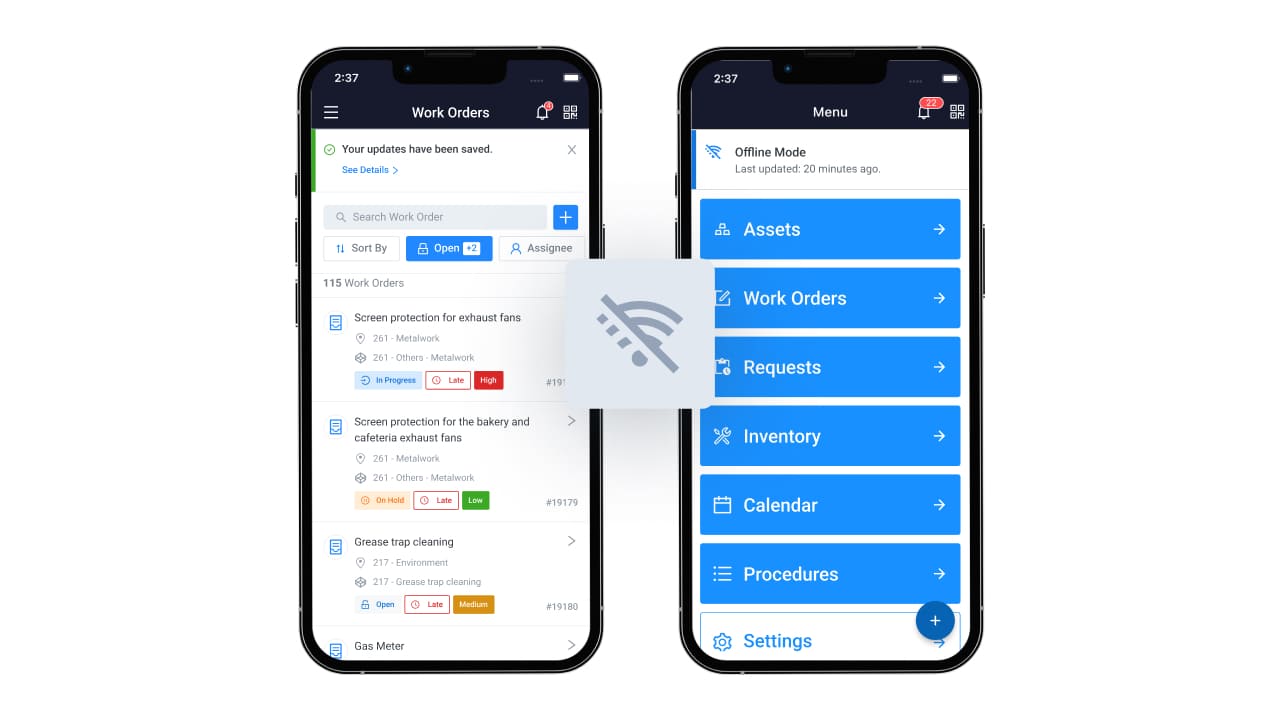

- Assets: Gain a full view of all industrial assets in the factory. This includes machinery, equipment, systems, and other critical elements. Detailed information about each asset, like its current status, maintenance history, and real-time performance data, is essential for making informed decisions. Identify assets that require top priority attention, schedule preventive maintenance, and optimize resource allocation. Even in offline mode, you can view all recorded information using QR codes to quickly access machine data or by searching for the asset name.

- Work Orders: Create, schedule, and track the execution of preventive, predictive, and even corrective work orders. Assign tasks to technicians, set deadlines and priorities, and get updates on their progress. This ensures the efficient execution of maintenance tasks and reduces unplanned downtime. And even without service, you can still open and manage work orders as usual.

- Requests: Maintenance requests can also be created and managed online or offline. Describe the issues and link them to assets. Easily manage these requests by reviewing and tracking them, even in remote or hard-to-reach sites. This ensures that no important request goes unanswered and maintenance needs are addressed promptly.

- Inventory: Inventory management is essential to ensure that spare parts and necessary components are available when needed. The TRACTIAN App helps maintain a detailed record of spare parts inventory, making timely restocks easy and preventing operational disruptions due to essential parts shortage. As soon as a machine needs a part replacement, the entire process from order to stock can be handled through the app.

- Calendar: The in-app calendar allows for effective scheduling and coordination of maintenance activities. Managers can quickly see scheduled PMs and key dates, aiding in long-term planning and ensuring that resources are available when needed.

- Procedures: Maintenance procedures are essential to ensure that tasks are consistently executed and following best practices. Even in offline mode, the TRACTIAN App allows maintenance procedures to be documented and accessed in a centralized, remote, and convenient manner. Managers can ensure that technicians have access to the necessary instructions and guidelines to perform tasks with all necessary safety measures.

- Monitoring: Asset monitoring and AI-generated alerts offered by the TRACTIAN App represent a revolution in maintenance management. They allow maintenance teams to monitor asset condition in real time, providing precise data on machine health and performance. Through the use of advanced sensors and technology, the platform detects even the subtlest signs of equipment problems or wear, enabling users to take preventive measures before potential failures occur. Real-time alerts instantly notify maintenance managers, speeding up response time and minimizing unplanned downtime.

The TRACTIAN App simplifies maintenance management and data acquisition, enabling mobility to be 100% available anytime and anywhere.

Keep Operations Under Control at All Times

One of the main concerns of any maintenance manager is maintaining control over operations. The TRACTIAN app addresses this issue head-on by providing a tool that allows for total control, even in locations where connectivity is an issue.

Managing industrial maintenance can be a challenge, but with mobility, offline capability, and advanced management tools, the TRACTIAN app becomes your perfect ally for maintaining control anytime, anywhere. Don’t fall behind in maintenance management – get a demo and find out how the TRACTIAN app can revolutionize your operations today!

Almost there, !

We just need a few more informations: