TRACTIAN Announces New Patent on Fault Detection Technology

Thanks to the success our clients have experienced with our condition monitoring solutions, we decided to showcase the transformative nature of our unique fault detection technology by filing a patent application with the United States Patent and Trademark Office.

Now, after years of extreme testing and validation, our technology has been recognized by the USPTO as being truly unique – and possibly one of the most advanced – in the predictive maintenance market. We are thrilled to announce this exciting step that demonstrates our commitment to providing innovative hardware and software solutions that make a measurable difference for our clients.

The patent was approved and issued in August 2022.

One of the standout features of TRACTIAN technology is the innovative approach we take to handling data collected by condition monitoring sensors. In addition to detecting issues and alerting when something is amiss, our technology goes a step further by offering specific diagnoses for each failure mode and providing maintenance managers with targeted solutions for addressing the problem. This empowers them to take quick and effective action to resolve any issues that may arise.

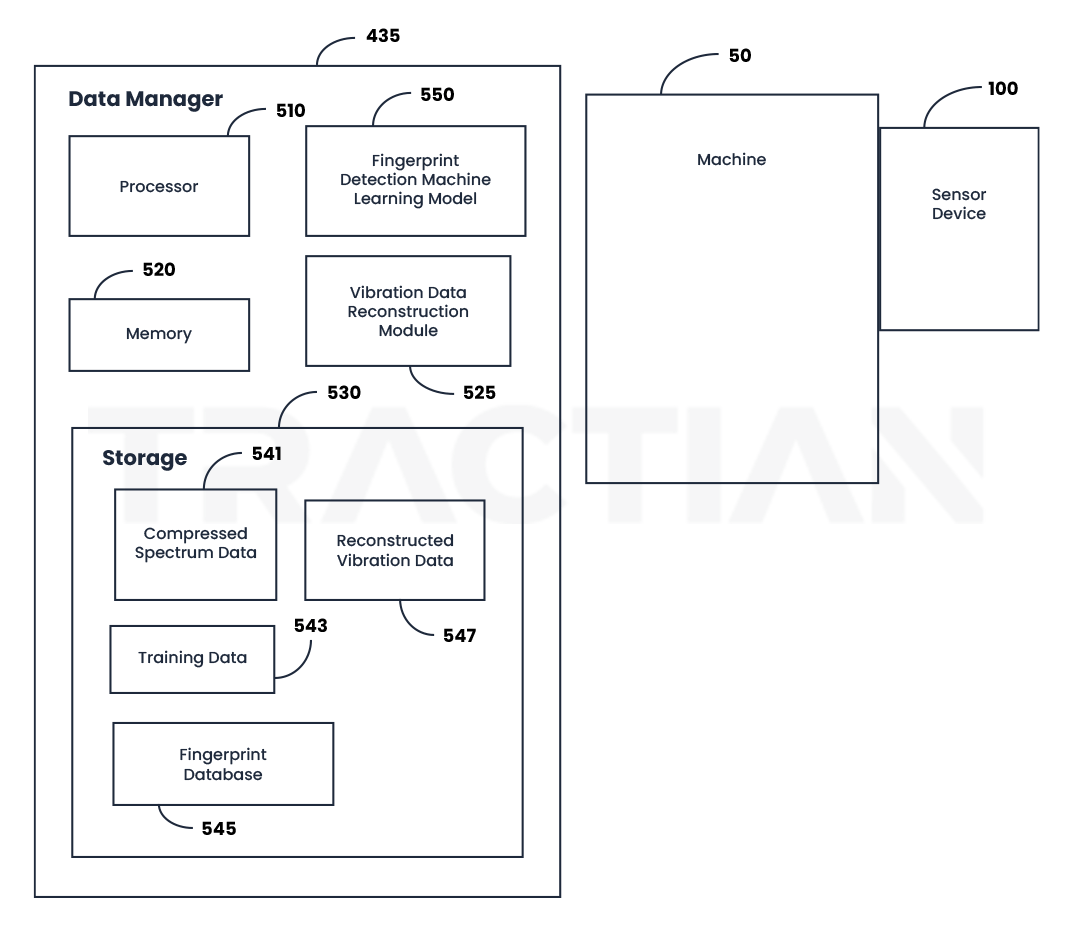

Our sensor device is designed to detect vibrations from a mechanical machine and transmit that data to a remote processing device for analysis. The processing device houses a machine learning model that has been trained to recognize certain motion patterns associated with error conditions in the machine.

By applying this model to the reconstructed vibration data, we are able to detect and predict the occurrence of error conditions in the machine based on the unique ‘fingerprint’ signal it generates.

Upon detecting an error condition, our system sends an alert to a human operator, who investigates the status of the machine and verifies that a fault has occurred. To ensure that our machine learning model is able to continue accurately detecting and predicting error conditions in the future, we update its training data with the vibration data generated by the machine during the fault. This allows the model to continue improving and refining its predictions over time.

‘We know there are other solutions that detect faults or claim to do so, but only the TRACTIAN system is capable of assertively identifying the failure mode and prescribing actions plans. So, we are happy to know that the USPTO agrees with us.’ – Igor Marinelli, Co-CEO of TRACTIAN.

How does the TRACTIAN failure prediction system work?

Let’s use Smart Trac as an example, which monitors vibration and temperature online. The sensor has a data acquisition frequency of 32kHz, but the biggest difficulty was sending that data to the cloud. Until now.

The patent defines a method for compressing this data. When attached to a machine, the sensor identifies vibration data and sends it for processing. This process involves a machine learning model trained to examine the data and identify patterns associated with a failure.

Innovation in condition-based monitoring

Anticipating failures with accuracy and precise diagnoses minimizes the downtime of assets, makes production more efficient, and cuts costs for companies – data is the key to transforming reliability and success in industrial plants.

Achieving this patent is a major accomplishment for the TRACTIAN team, and it underscores our dedication to supporting front-line maintenance professionals with the most advanced and effective solutions available.

Almost there, !

We just need a few more informations: