Machines and Teams:

Now in sync with Tractian

Stay ahead of failures, prevent downtime, and drive reliability across your plant with AI-powered Condition Monitoring and CMMS.

Stay ahead of failures, prevent downtime, and drive reliability across your plant with AI-powered Condition Monitoring and CMMS.

Call us now at

+1 (833) GET-TRAC

Trusted by U.S. and Global Manufacturers

From decision-makers to hands-on problem solvers, Tractian works for you.

A single pane of glass to manage maintenance, monitor machines, and optimize production processes.

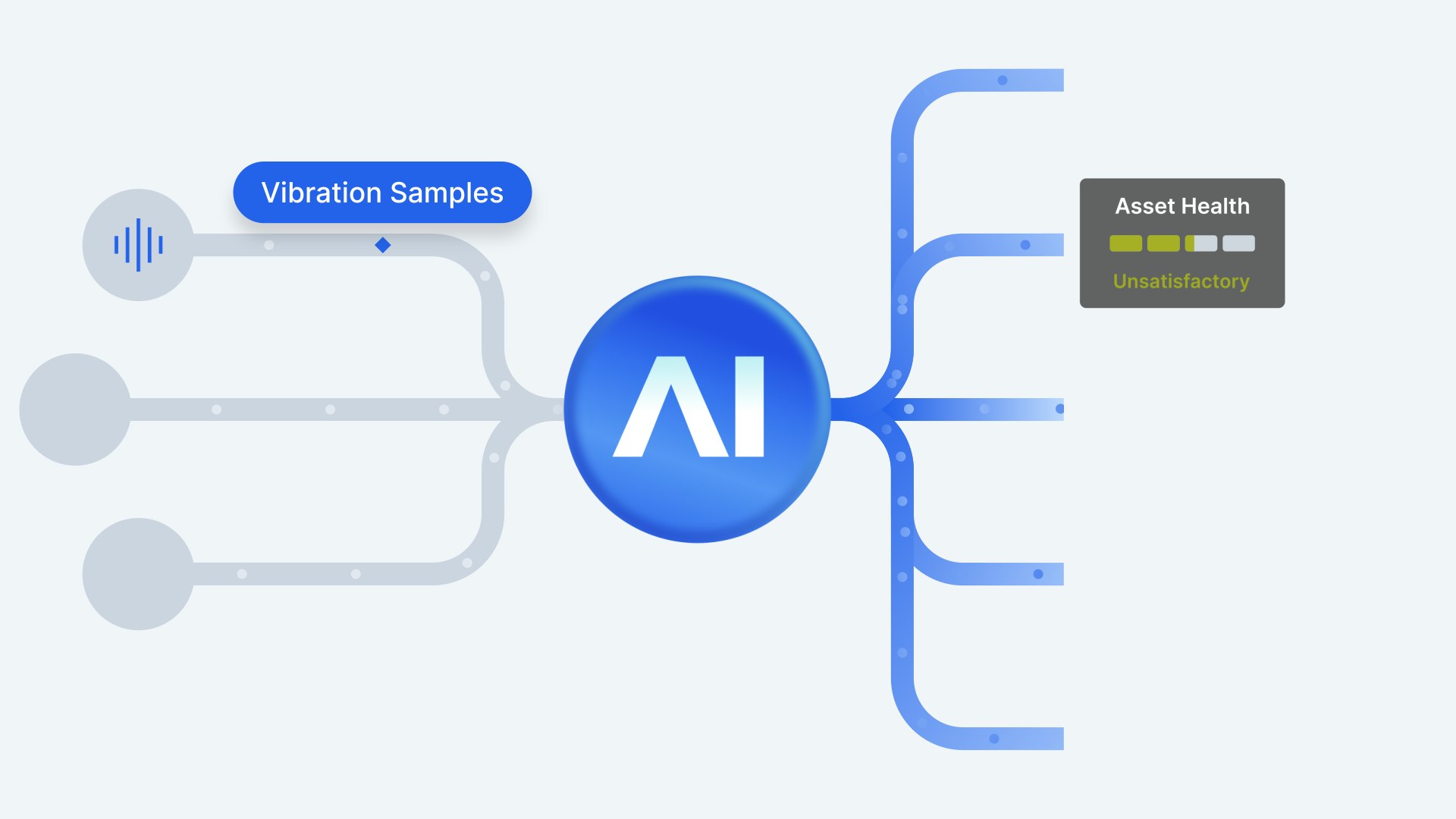

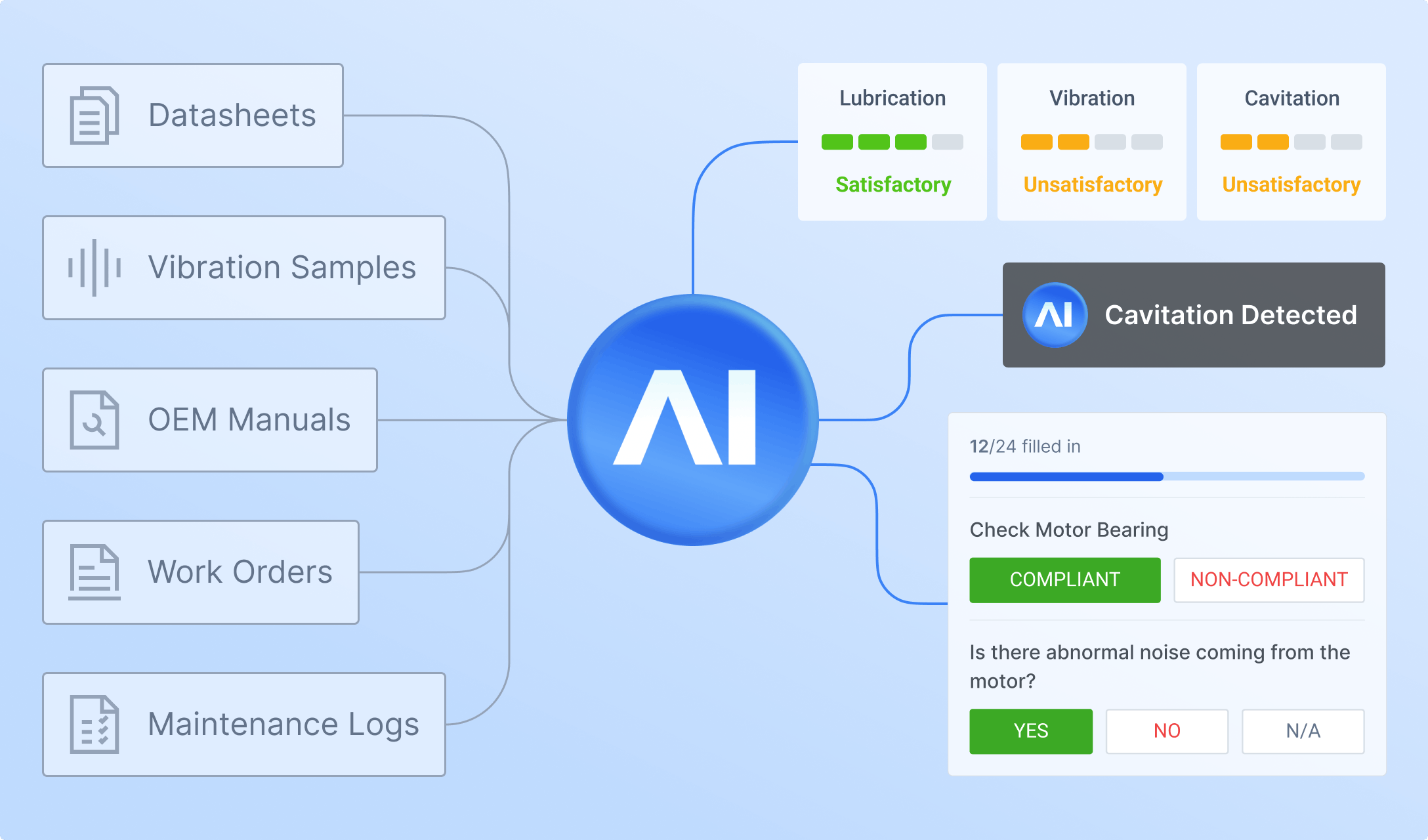

Condition Monitoring: predict failures, avoid downtime, and cut operational costs.

Monitor machines

Maintenance Management & Reliability: log every task and manage real-time data.

Manage assets

Smarter Operations & Data Intelligence: transform process data into profits.

Optimize processes