A solution for every stage of your maintenance operations.

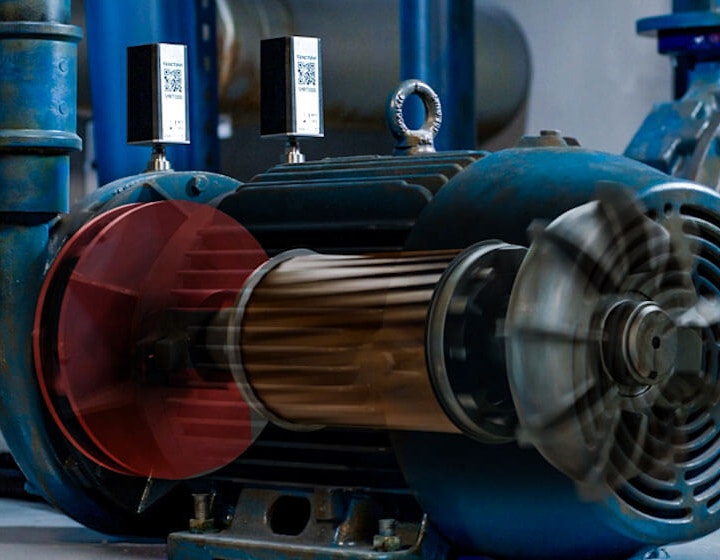

CbM Sensor

Smart Trac Ultra

Condition Monitoring & Auto Diagnosis™: predict failures, avoid downtime, and cut operational costs

Learn MoreCMMS Software

TracOS™

Maintenance Management & Reliability: register every task and manage real-time data

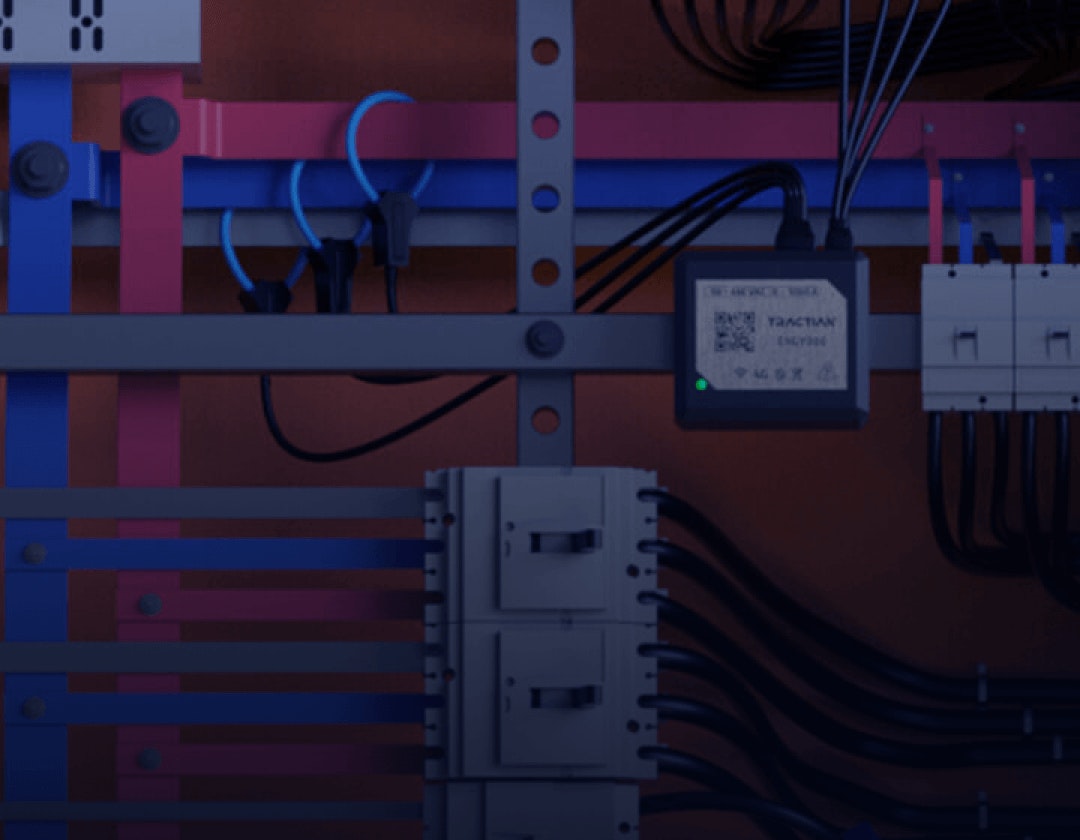

Learn Moreenergy efficiency

Energy Trac

Energy Efficiency & Data Intelligence: transform energy consumption data into profits

Learn More