Condition Monitoring for Food & Beverage Companies

The brands you trust most invest in Artificial Intelligence for efficient and reliable maintenance.

Average ROI

1600%

Average Payback

10 days

Availability Increase

170 hours

Monitored Assets per Factory

3200

Results Proven by Real Data from Our Clients

Predictive Asset Monitoring

170 hours

of machine downtime avoided by Predictive Monitoring

$ 1 million

saved in multinational food companies

3,000+ failures

identified in the sector

$ 110,000

in average savings per failure

X-Ray: Maintenance in the Food Industry

Main Critical Assets Monitored by TRACTIAN

Most Common Failures

TRACTIAN online condition monitoring sensors are compatible with 100+ asset categories and monitor many critical machines in the food & beverage industry.

Each identified failure avoids equipment breakdown and unplanned downtime. Maintenance teams also get AI-powered reports and diagnostics to understand how to act and prevent similar problems in the future. Depending on the failure, savings can exceed $ 600 thousand.

Processes with High Contamination Risk Require Cutting-edge Technology

The food industry is one of the sectors that invest the most in technology, but how does maintenance work in these companies?

42%

have online condition monitoring strategies for critical equipment

67%

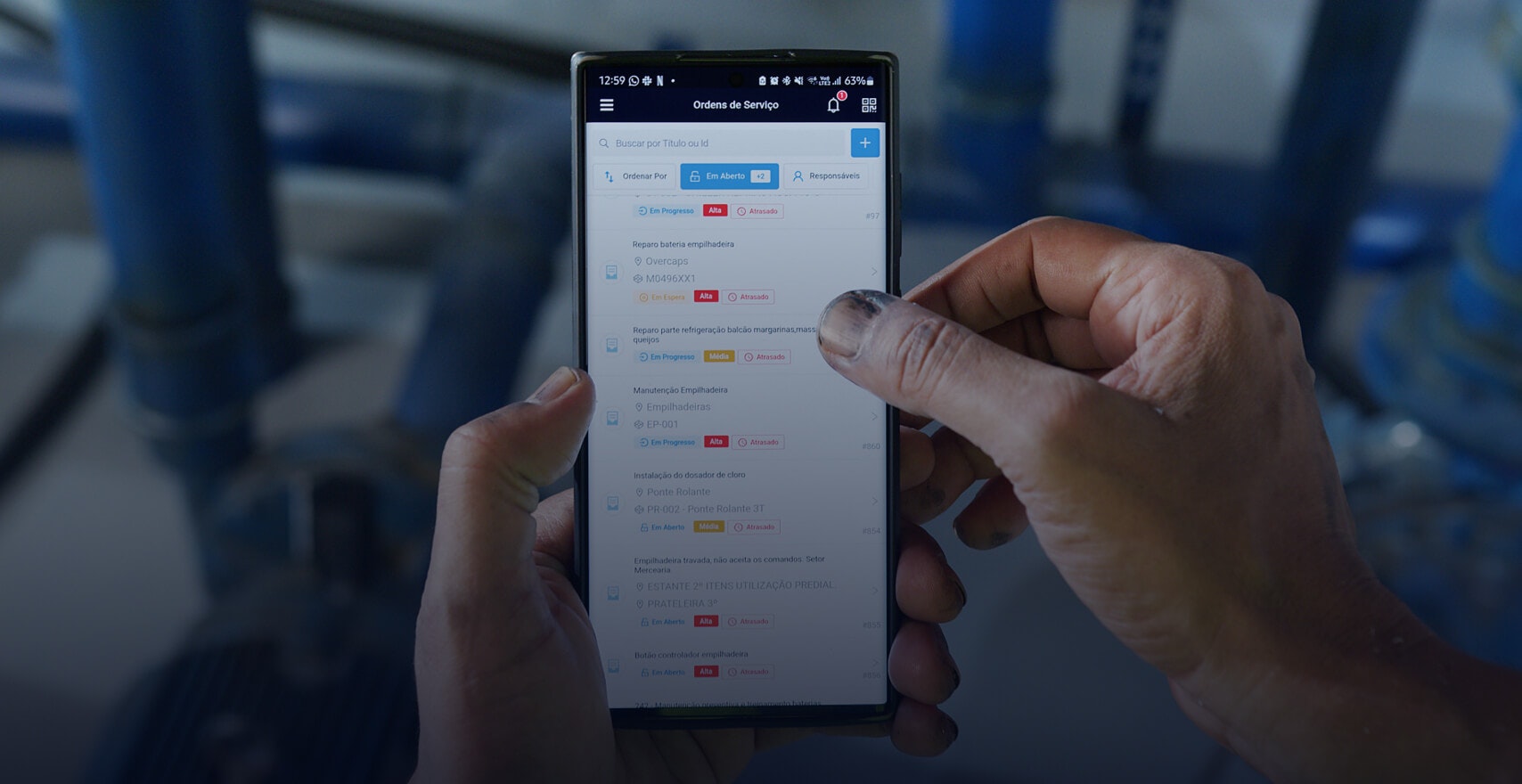

use phones and tablets on maintenance routes for mobile-first data

84%

use SAP or other ERPs, which are strengthened when integrated with TracOS™

Food Industry: A Pillar of US Economy

The food industry accounts for 5,4% of US GDP and generates 10,5% of US employment*, it deserves maintenance management to match its relevance.

*Data from 2021, taken from the Economic Research Service of the U.S. Department of Agriculture.

In order for the food to get to your table safely, companies must meet various health standards required by regulatory agencies. Every step of the production processes is specifically designed to encompass topics such as:

Food Perishability

Food Safety

Product Quality

And well-performed maintenance is essential in order to achieve these quality standards. With TRACTIAN Artificial Intelligence, food & beverage industries can attain:

More Predictability in Maintenance

More Control Over Production

Increased Operational Safety

Processes That Ensure Quality and Safety of What You Consume

Main Failures in Mixers

Mixing

Combines materials and components in different states, creating a homogeneous product.

Main Failures in Mixers

Shaft or blade breakage

These components can be exposed to intense mechanical loads during the mixing process. When subjected to excessive force, they can break, disrupting the operation.

Component wear

Blades, shafts, bearings, and gears can wear out due to friction and continuous use.

Main Failures in Mills

Grinding and Milling

Reduces the size of solid raw materials such as grains and cereals to obtain final products such as flours and powders.

Main Failures in Mills

Mechanical problems

Excessive wear of hammers or rollers, clogging of the feeding system, breakage of sieves or grids.

Inadequate lubrication

May cause excessive friction between parts, which can lead to failure and breakage.

Main Failures in Furnaces

Cooking

Applies controlled heat to products to promote proper cooking, developing texture, flavor and aroma.

Main Failures in Furnaces

Accumulation of debris

The build-up of grease and food debris can happen inside the furnace and reduce efficiency, besides posing a fire hazard.

Heat leakage

Can lead to loss of energy efficiency.

Damage to motors and fans

These are used for air circulation. If they get damaged, heat distribution will be compromised.

Main Failures in Filling Machines

Bottling or Packaging

Packs the products in an appropriate way to preserve their quality and integrity.

Main Failures in Filling Machines

Blocking or locking

It can happen due to foreign objects entering the feeding system.

Leaks

Pipes, fittings or seals may leak.

Component wear or failure

Gears, belts, bearings or motors can wear out over time.

Technology That Generates Reliability and Results

Monitoring that adapts to your process.

TRACTIAN monitoring creates a massive database to understand the vibrational behavior of equipment. The AI identifies different operating modes, and automatically determines the vibration limits for each one. Process-tailored, prescriptive insights are the best way to have assertive alerts and identify real failures.

Drive motor of a Hammer Mill

Operating Modes

Rice Processing

Beans Processing

When monitoring the sugar mill, TRACTIAN sensors issued an automatic bearing looseness alert, with an exact, AI-generated prescription on what to do to avoid a failure.That enabled the team to avoid a week of unplanned downtime. After the technicians performed maintenance using shop floor expertise combined with the prescriptions generated by AI, vibration levels returned to normal.

Give Your Team Autonomy with a Maintenance-dedicated Platform

Reliable Maintenance Enables the Highest Quality Products.

Get a demo.