How Munksjo Increased Reliability with Prescriptive Insights

Eye on Failure is a series of articles highlighting the stories of maintenance workers who have benefited from TRACTIAN by eliminating failures and unplanned machine downtime. To see other cases such as Embraer and AmstedMaxion, visit our blog.

The company

Ahlstrom Munksjö is a global leader in fiber-based materials with customers worldwide. Headquarted in Finland, they also have sites across Europe, Asia and both North and South America.

A long path of knowledge

Pedro Henrique Nogueira started his career at the company as an electrical trainee in 2018. Two years later he was promoted to metrology assistant. Pedro never let his lack of field experience delay his growth. Instead, he studied new technology and best practices that are essential to the growth of his field.

Since I joined Ahlstrom, I’ve gotten to learn more about other fields of maintenance and participated in great projects, such as the implementation of the SAP PM module.

Maintenance insights that saved the day

Pedro explains that his plant has been established in his city for over a hundred years. Therefore, introducing Industry 4.0 was very complicated due to the already established culture. In addition, most assets required constant maintenance, as they operate every day of the week.

Before TRACTIAN, machine health was supervised by an outsourced maintenance company that did a predictive analysis once a month by sampling data at each vibration spot. A while later, they would send a report and history on the state of each asset.

Pedro says that performing accurate maintenance was complicated because information sampling was only done monthly. Another big problem was the delay in receiving the final report and diagnosis.

Check out our complete guide to Predictive Maintenance

The need to improve these maintenance processes became more apparent as equipment faults increased and unplanned downtime was a constant reality.

That’s where TRACTIAN came in. Initially, the company started with 10 sensors to learn more. After only two months, the team saw enough benefits to upgrade to 33 sensors.

The ease of access and reliability of TRACTIAN then made Ahlstrom quickly expand to 77 sensors in the following 2 months. By monitoring more equipment, the effectiveness of the data and repair routines increased. This reflected the importance of their maintenance teams’ daily routine and overall satisfaction.

When we started to monitor machines remotely, there was no need to be on-site anymore.

Thanks to this innovative way of performing maintenance, two motors with bearing failures and incorrect fastening were detected. Before an emergency stop could happen, the bearings were replaced which saved two machines from breaking down.

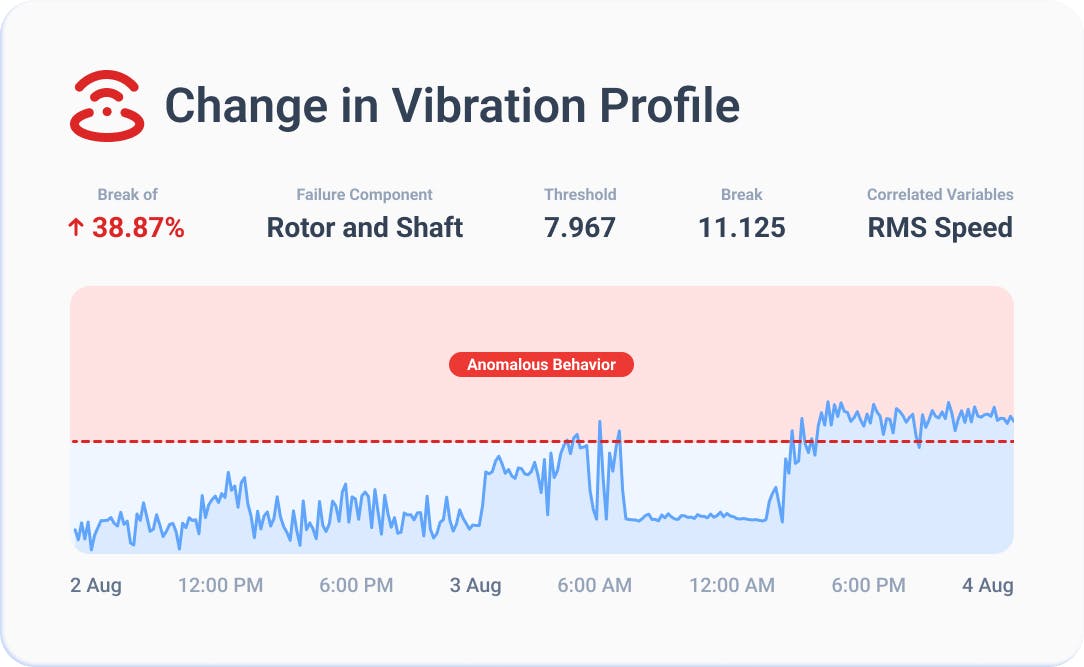

In another instance where the limit was 8.9649 and the rate reached was 12.4500, a rupture of 38.87% more than acceptable was detected by the sensor. This change in the vibration profile populated an alert in the platform which allowed the maintenance team to act before a more serious problem occurred.

The sensors make the life of maintenance professionals easier. By providing a more precise analysis of what’s happening with the equipment and why they’re experiencing problems, you can evaluate the asset and it’smlocation entirely.

Now, Ahlstrom has acquired 30 more sensors while Pedro and his team are looking forward to expanding their condition monitoring system.

We have real-time monitoring. This is awesome because I can be at home and know if all these machines are running or if there’s been a problem. I can monitor them and see if the equipment is malfunctioning, and it doesn’t matter what day it is or where I am.

The sensors alleviated a lot of the high costs associated with maintenance. For example, the platform alerted to an engine that was showing a problem with its bearing. This could have locked it and even burned the entire engine. Thanks to the engine’s sensor, a failure was avoided. The company only had to pay for a replacement bearing instead of a brand-new motor.

Learn all about electric motor maintenance

Why did Ahlstrom Munksjo choose TRACTIAN?

According to Pedro, a sensor that collects so much information and has several functionalities at an affordable price is simply fantastic. The ease of communication between his team and the platform is another benefit that receives a lot of positive feedback within the company.

“You don’t need to have a network integrated into the sensor. It does this with a smartphone mobile signal and it made our life here much easier. We don’t have to involve other areas or complicated cables because everything is done automatically. How easy the sensors are to set up is also something to highlight.”

If you want to increase machine effectiveness and reliability, follow in Pedro’s footsteps: talk to our experts to join TRACTIAN and leave conventional maintenance behind.

Almost there, !

We just need a few more informations: