OEE SENSORS TO EMPOWER THE FRONTLINE

Make every operator a production superstar

With AI-powered sensors and software, you get live visibility, shift-level data, and clear feedback to reduce performance gaps and unlock your team’s potential.

Make every operator a production superstar

With AI-powered sensors and software, you get live visibility, shift-level data, and clear feedback to reduce performance gaps and unlock your team’s potential.

OPERATOR PERFORMANCE THAT DRIVES RESULTS

When the team relies on end-of-shift reports, radios, or manual logs, issues go unnoticed and delays stretch longer than they should. Small slowdowns, unclear ownership, and miscommunication add up to missed targets and unstable shifts.

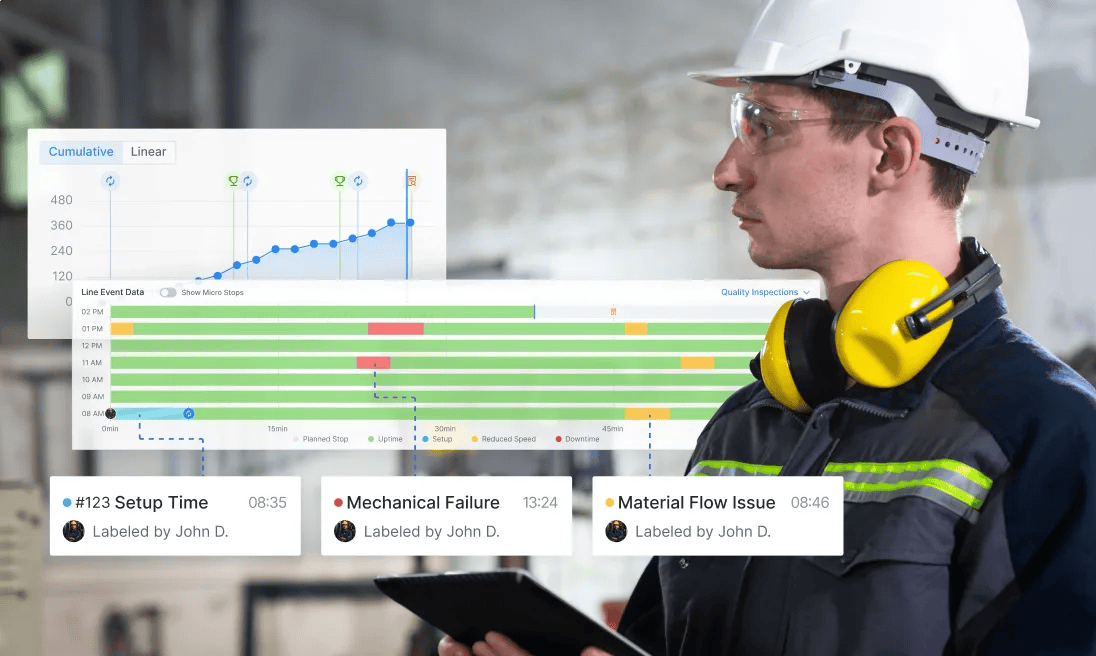

Operators start each shift with clear goals, see live station performance, label downtime as it happens, and communicate directly with the right teams. Performance is visible, shared, and actionable, so issues are resolved faster and shifts stay on track.

15%

Improvement in shift output

2x

Increased operator engagement

10%

Faster setups and responses

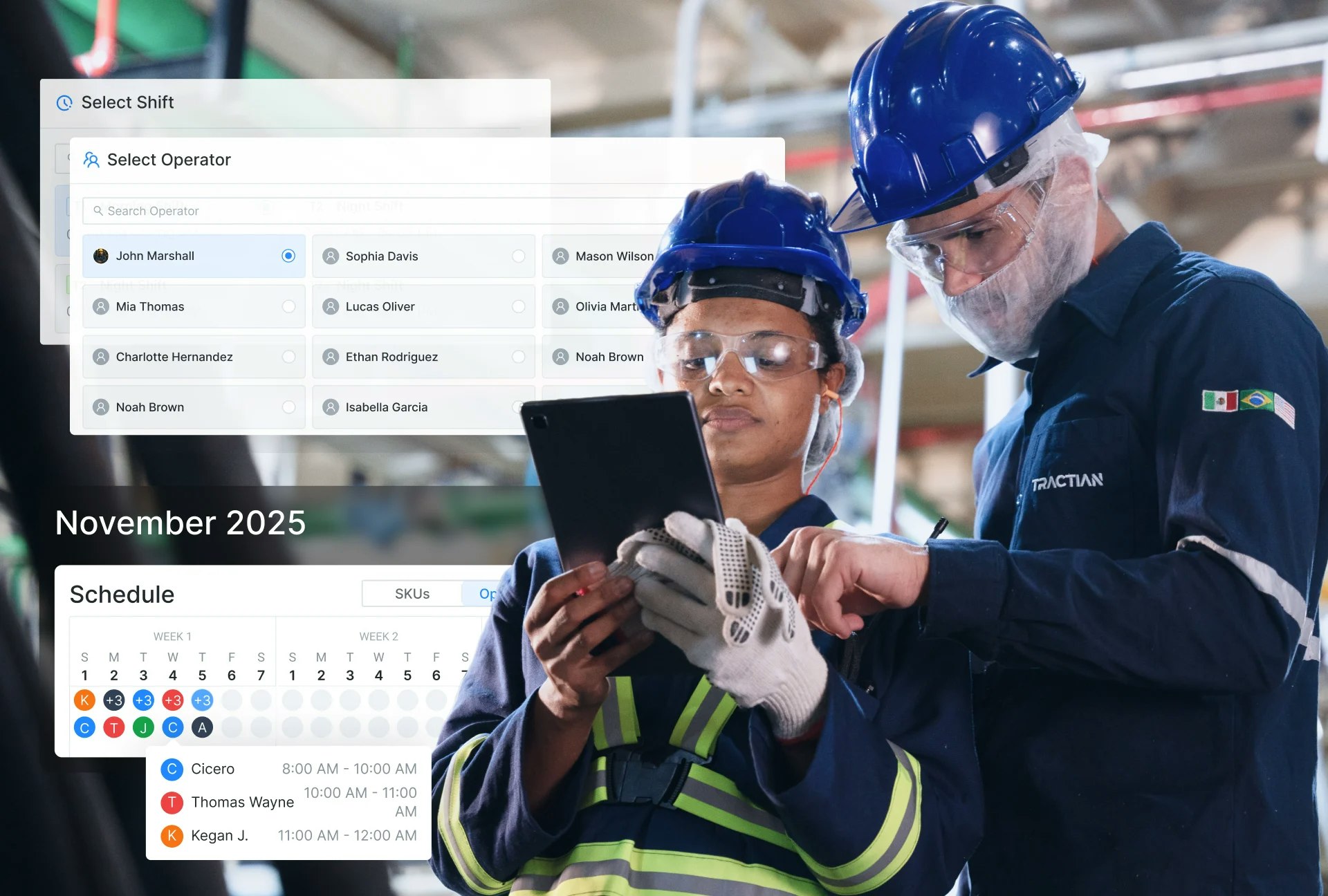

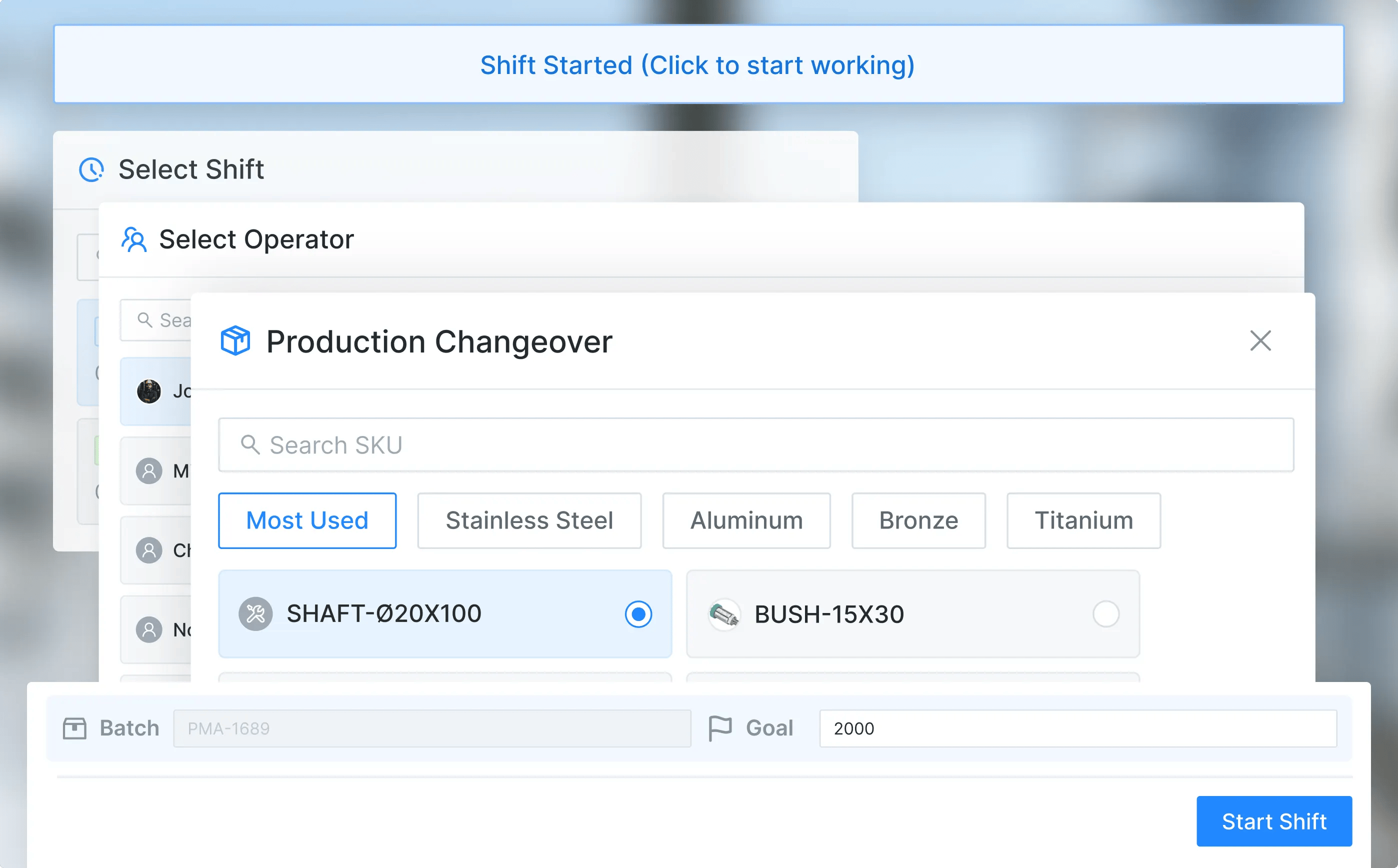

Operators identify themselves, select their station, and confirm the SKU before work begins. This creates clean, real-time production records from the moment the line starts.

Operators don’t just clocking in, they drive outcomes. Tractian gives them live visibility, feedback, and communication tools to act fast, get aligned, and win shift over shift.

Active Engagement

Shorten reaction times and support steadier, more efficient output with a mobile and tablet ready interface delivering day-to-day production insights and integrated chat in one place.

Encouraged Ownership

Individualized performance feedback and clear OEE impact indicators drive greater accountability for cycle times, changeovers, and downtime recovery.

Shared Source of Knowledge

Live machine states, operator metrics, and shift comparisons are presented on a single unified platform so every role works from the same real-time data set, reducing misalignment and improving production decisions across the line.

Proprietary IoT sensors tap into analog and digital inputs, current readings, and PLCs, ensuring full compatibility with your systems.

Built for security, reliability, and continuous uptime, our hardware is backed by SOC 2 Type II and ISO 27001 certifications.

Real-time analytics monitor the status of your machines, track OEE, identify downtime causes, and discover hidden inefficiencies.

Get a live walkthrough and pricing tailored to your plant.

FAQ